As you consider the efficiency and sustainability of industrial processes, you can’t help but think about the role of fluid coupling technology. Advances in this field have led to significant improvements in performance and reliability, making it an essential component in many industries. But what exactly makes these modern fluid coupling designs so effective? By harnessing advanced materials and innovative geometries, these solutions minimize energy losses and optimize performance. But just how much of an impact can they have on your operations, and what other innovations are on the horizon that could further transform your industry?

Modern Fluid Coupling Designs

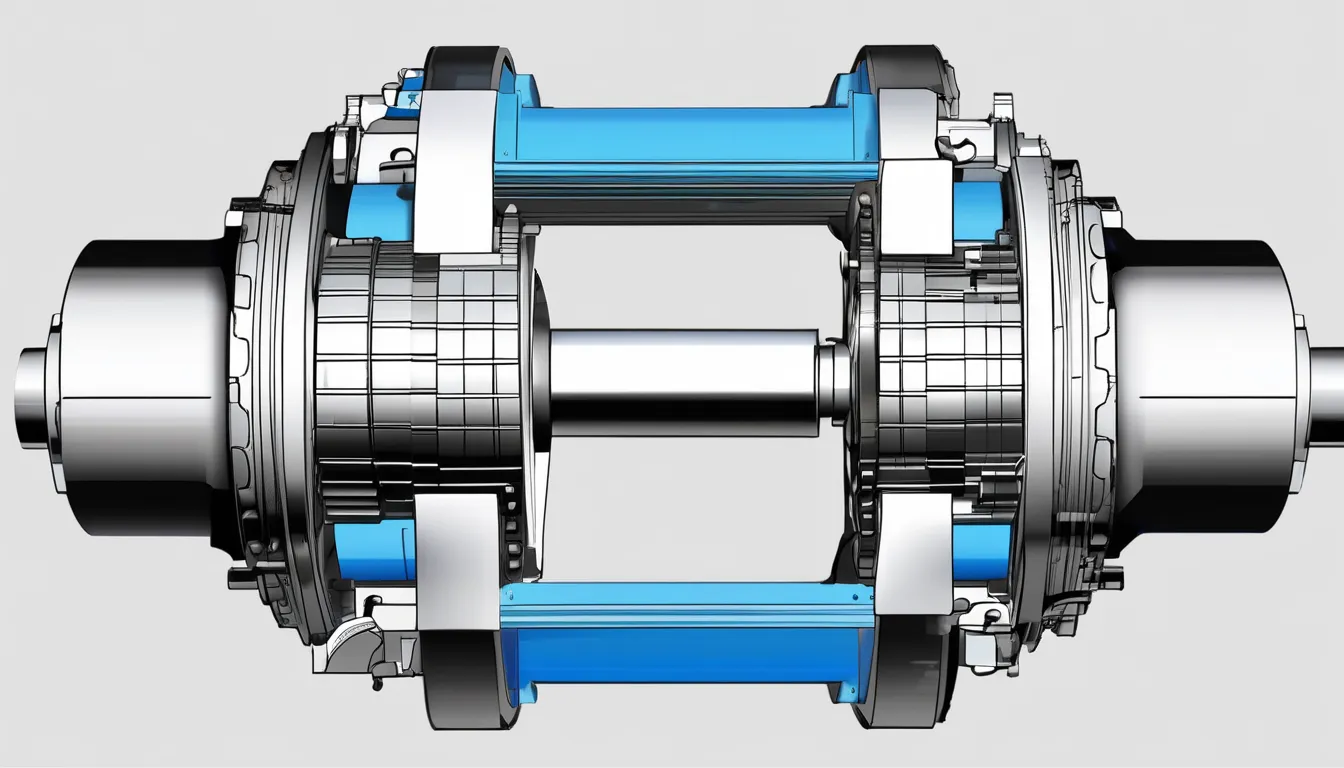

Most modern fluid coupling designs incorporate advanced materials and innovative geometries to deliver improved efficiency and reliability. You’re likely familiar with the traditional fluid coupling designs that have been in use for decades.

However, these newer designs take it to the next level by utilizing cutting-edge materials such as high-strength steel, advanced ceramics, and specialized polymers. These materials enable the fluid coupling to withstand harsher operating conditions, including higher temperatures and pressures.

When you’re working with fluid couplings, you want them to be able to handle the demands of your application. That’s why modern fluid coupling designs often feature innovative geometries that enhance the flow of fluid and minimize energy losses.

These geometries can include optimized impeller shapes, improved seal designs, and enhanced bearing configurations. By incorporating these advanced features, you can expect improved performance, reduced downtime, and lower maintenance costs.

As a result, modern fluid coupling designs are becoming increasingly popular in a wide range of industrial applications, from power generation to oil and gas processing.

Energy Efficiency in Industry

When you’re evaluating the performance of modern fluid coupling designs, energy efficiency is likely a key consideration.

As you assess the impact of fluid coupling technology on your industrial processes, it’s essential to consider the role it plays in reducing energy consumption. By optimizing fluid coupling designs, you can minimize energy losses and maximize efficiency.

Some of the key benefits of energy-efficient fluid coupling designs include:

- Reduced energy consumption: By minimizing energy losses, you can lower your overall energy costs and reduce your environmental footprint.

- Increased productivity: Energy-efficient fluid coupling designs can help you achieve faster cycle times and increased throughput.

- Extended equipment life: By reducing the stress on your equipment, you can extend its lifespan and minimize downtime.

- Lower maintenance costs: Energy-efficient fluid Fluid Coupling designs often require less maintenance, which can help you save time and money.

Intelligent Coupling Systems

A growing number of industrial applications now rely on intelligent coupling systems that integrate advanced sensors and control algorithms to optimize fluid coupling performance. These advanced systems allow you to monitor and adjust fluid coupling parameters in real-time, enabling you to fine-tune your process for maximum efficiency.

With intelligent coupling systems, you can automatically adjust the speed of your fluid coupling to match changing process conditions, reducing wear and tear on your equipment and minimizing downtime.

You can also use intelligent coupling systems to detect potential problems before they occur. Advanced sensors and machine learning algorithms can analyze data from your fluid coupling and predict when maintenance is required, allowing you to schedule maintenance during planned downtime.

This proactive approach helps you avoid costly repairs and reduce the risk of unexpected equipment failures. By integrating intelligent coupling systems into your industrial process, you can improve efficiency, reduce maintenance costs, and increase overall productivity.

Environmental Impact Reduction

Several key innovations in fluid coupling technology are helping you significantly reduce your environmental footprint.

As industries strive for sustainability, fluid coupling technology has evolved to minimize energy consumption, lower emissions, and reduce waste.

By optimizing the performance of fluid couplings, you can decrease the energy required to operate your systems, resulting in lower greenhouse gas emissions.

Some of the ways fluid coupling technology is reducing environmental impact include:

- Improved Efficiency: Advanced fluid coupling designs minimize energy losses, reducing the amount of energy required to operate your systems.

- Low-Maintenance Designs: New fluid coupling designs require less maintenance, reducing the need for replacement parts and minimizing waste.

- Optimized Cooling Systems: Advanced cooling systems reduce energy consumption and minimize the use of water and other resources.

- Integrated Monitoring Systems: Real-time monitoring systems enable you to quickly identify and address any issues, reducing downtime and minimizing environmental impact.

Advancements in Materials Technology

Advancements in materials technology are revolutionizing fluid coupling design, enabling you to build more durable, efficient, and sustainable systems. You’re now able to select from a wide range of materials that offer improved performance and reduced maintenance.

For instance, high-strength composites can withstand extreme temperatures and corrosive environments, while advanced polymers provide excellent wear resistance and chemical stability.

New materials also allow for more compact designs, reducing the overall size and weight of fluid couplings. This, in turn, minimizes energy losses and increases system efficiency.

Moreover, some materials can be recycled or reused at the end of their lifespan, reducing waste and environmental impact.

When designing your fluid coupling system, you can choose from a variety of materials, each with its unique properties and benefits.

Conclusion

You’re witnessing a revolution in industrial processes with fluid coupling technology. Modern designs are optimizing performance and reducing energy consumption. Intelligent coupling systems are integrating real-time monitoring, enabling predictive maintenance and minimizing downtime. By harnessing advanced materials and innovative geometries, you’re achieving reduced environmental impact and increased productivity. These innovations are transforming industries, and you’re at the forefront of a more efficient and sustainable future.